UFactory

They were showing their new xArm 7 which is a 7-DOF light-weight, table-mounted robot arm (Fig. 3-5).

The robot was doing machine-tending duty for an Espresso Coffee machine.

Its design borrows from other collaborative manipulators like the Kuka iiwa or Franka Emika.

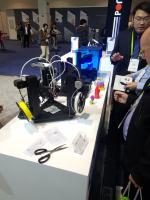

They also had their little uArm Swift which is designed for education or Makers.

It was drawing a picture using a laser engraver (Fig. 2).

Website: www.ufactory.cc

Dobot (Shenzhen Yuejiang Technology Co. Ltd)

They were demonstrating their M1 table-mounted robot arm, designed for pick-and-place, 3D printing, laser etching or PCB soldering (Fig. 8-10). It’s the first low-cost SCARA type arm, which is a design that can allow higher rigidity and accuracy of motion. It has 2 DOF on the horizontal plane and 1 DOF vertical, using a linear actuator.

They were also showing their 4 DOF robot arm called “Magician”, designed for education (Fig. 11). Its design locates two motors in an opposing position at the shoulder, which is a nice weight-saving idea that reminds me of the design of the Scorbot educational robot.

They also had their “Rigiet”, a stabilizing gimbal for smartphone cameras (Fig. 12), and a 3D printer called “Mooz” (Fig. 13).

Website: www.dobot.cc

ITRI (Industrial Technology Research Institute)

This group was again showing their dual-arm robot, to demonstrate their “Intelligent Vision System for Companion Robots”.

This time it was playing Scrabble against a human opponent.

It utilizes a custom stereo camera, two 7 DOF arms from Universal Robotics and parallel-jaw grippers from Robotiq.

Website: www.itri.org.tw/intelligent-vision-system/

RoboMantis by Motiv Robotics

A tele-operated robot with 4 wheel-legs and one arm. It’s based on the RoboSimian robot that JPL developed for the DARPA Robotics Challenge.

Website: www.motivrobotics.com

Smart Robots

They had a demo showing a gesture-controlled robot that could grasp objects.

The system consists of an arm from Universal Robots and a 3D camera system. The camera is basically a Microsoft Kinect v2 in a custom, white plastic casing. The robot can detect and track human posture (skeletons), recognize gestures like a hand making a “stop sign”, and stop moving if you put your hand into its work area.

Website: www.smartrobots.it/en/

|

Fig. 19: |

Fig. 20: |

Iteca

They had a small Comau robot arm performing a simple pick-and-place task.

This was to demonstrate their “SmartUpp” and “Digital Twin” software, which can be used to interface with and simulate an industrial robot.

Website: www.iteca.eu

Dunan Precision Inc.

They were using a robot arm from AUBO Robotics to demonstrate their vIMU (Visual IMU), a camera-based sensor that uses visual odometry to estimate motion. They also have a conventional IMU module.

Website: www.dunanprecision.com

Electric Loading

They have developed a prototype “Smart, ultra-rapid charging system for electric vehicles”.

It comprises of a Fanuc industrial robot arm with a tool changer and 3D camera mounted on the wrist.

Website: www.electric-loading.com/en

Other groups have already been looking at using robots to recharge EVs, including Tesla and Volkswagon.

|

Fig. 26: |

Nikon / Mark Roberts Motion Control

The “Bolt” is a series of industrial robot arms with cameras mounted on the wrist. It is designed for high-speed, motion-controlled cinematography.

They were doing a demo where people could pose for a high-speed “selfie” (Fig. 29).

Website: www.mrmoco.com/thebolt/